Drilling accurate holes require an accurate machine. This is where a drill machine or drill press comes in. This tool is made to provide more accuracy and power than a conventional handheld drill. I have owned drill presses for many years and it is my go-to tool when I do any kind of drilling. Early on in my career I decided to buy the best floor standing drill press I can afford and I have never looked back since.

There are many advantages to having a machine like this in your garage. In this article, we will look at some of those advantages and how to properly use your drill machine.

Contents

Primary uses of the drill machine.

Drill presses can perform tasks like drilling, sanding, countersinking, reaming and many more. This is a truly versatile tool that comes in many models and sizes, and a must for anyone doing large amounts of work in the garage. The primary function of a drill machine is to cut holes into the material.

This is done by lowering a rotating drill bit into the material or work-piece. Read our drill press reviews page to find the best drill press for your needs.

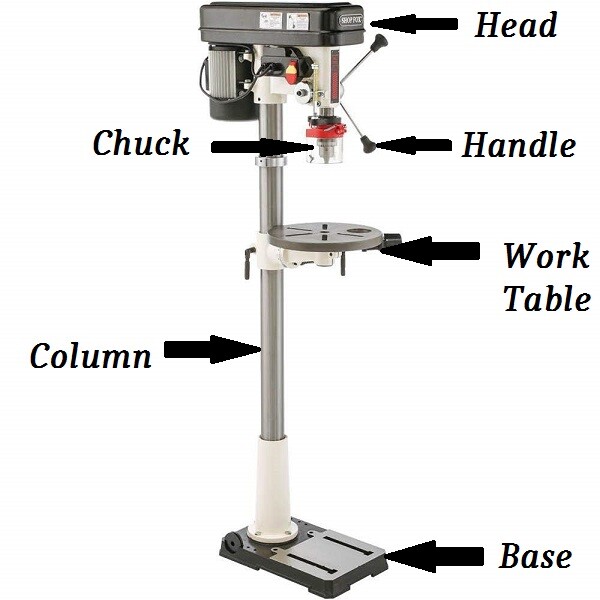

The drill press consists of four main parts; the base, the column; the work table and the head.

Head

The head of the drill consists of the motor and the spindle assembly. The spindle assembly is connected to a set of pulleys as is the motor. These two sets of pulleys are connected by a belt which drives the drill. This belt is interchangeable to provide different speed settings. A chuck is fitted to the spindle and this is what holds the drill bit.

Work Table

The work table is connected to the column and can usually be lowered or raised depending on the task at hand. Some drill presses feature work tables that can tilt which allows you to drill at different angles. The size of the work table is important as this will determine the size of the object you can work on.

The most important measurement is the distance from the centre of the chuck to the column. This is called the swing of the drill press and this will dictate the size of material that you can cut a hole in the centre.

The Column

The column is basically a metal shaft that holds the drill press together. The head is connected to the top of the column and the base is connected to the bottom of the column. The work table is fitted to the column in between the base and head and can slide up and down.

The Base

The base is the foot piece of the drill press. This provides stability to the machine. A good practice is to secure the base to the floor by using steel bolts. This will keep the machine in position and is much safer. The bigger the base, the better. This is what the better brands get right, for instance a Jet drill press will have a much bigger base than cheaper models like the Rockwell Shop Series and Skil 3320 drill press.

How to start drilling holes

To start drilling you need drill bits. There are many types of drill bits and the type of material you want to cut a hole into will determine what type of drill bit to use.

Drill bits are designed to serve a specific role and only be used on certain materials. The first thing you need to do is select the right type of bit, for instance, masonry, wood, metal etc.

Determine the size of the hole needed

This is not always as straightforward as it seems. Make sure that you know exactly the size of the hole that is needed and then select a drill bit that will cut that size hole. Drill bits are measured in inches or millimetres, depending on where you are.

Insert the drill bit into the chuck

After selecting the right bit, you need to insert the bit into the chuck of the drill machine. To open the chuck rotate it anti-clockwise until the bit can fit inside. Now rotate the chuck clockwise to tighten the bit in the chuck. First, do it just by hand and then tighten properly by using the chuck key.

Make sure the bit is tightened properly by switching the drill on for just a second. Make sure that the drill bit runs smooth and has no wobble that can affect the hole diameter.

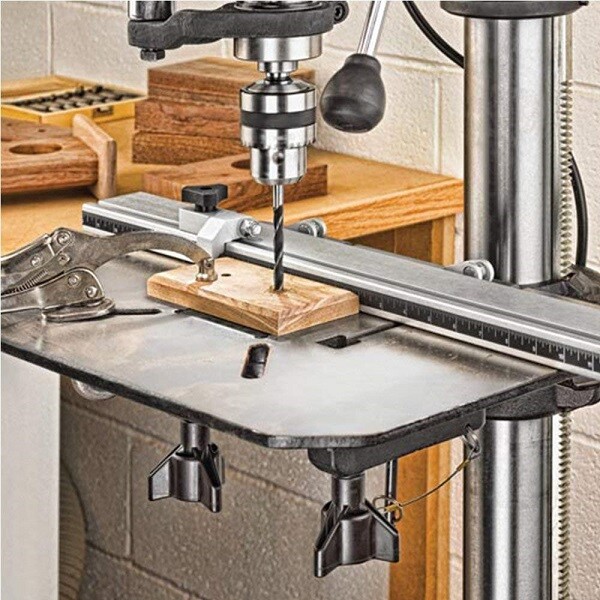

Place the workpiece on the work table

The next step is to place the material you want to drill into on the work table. First, mark the hole to be drilled with a pencil. This pencil mark needs to be aligned with the centre of the chuck.

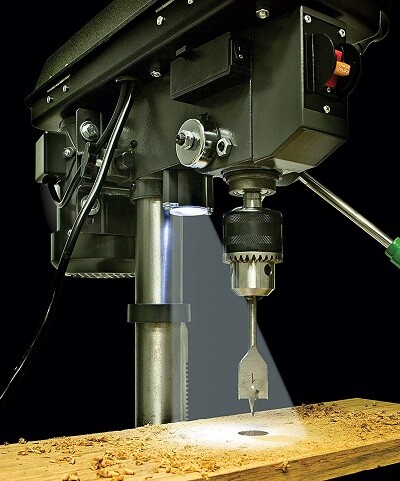

If your drill machine has a laser guide system, this is a very easy task. Just align the pencil mark with the cross of the laser and you’re ready to go. If you don’t have a laser guide, you will have to do it manually.

To manually align the marked hole with the drill bit you have to lower the bit until it is nearly touching the work material, then align the marked hole by positioning it right under the drill bit. Lower the drill bit completely to make sure it makes contact in the exact spot that you marked. When this is done, clamp the material to the work table to secure it in place.

Switch on the drill

You are now ready to switch on the drill press and start drilling the hole. Switch on the drill and make sure the bit still runs smooth. Lower the drill bit on to the workpiece by pulling the handle to lower the chuck. Don’t go too fast, slow and steady is much better.

Start drilling

Once the drill bit reaches the workpiece continue to pull down on the handle to drill into the material. There is no need to use force, let the drill do the work. Continue to pull down with moderate pressure until the hole has been drilled through the material.

Release the handle slowly ( Rotate away from you) to raise the drill bit away from the workpiece. That is all that there is to drill a hole with a drill machine. There are many more functions and settings that can be used and too much to discuss in just one article. The best way to conquer all the workings of this machine is to use it and try all the different settings.

Tips

Here are a few tips to remember when you use a drill press:

- Slow speed for metal

- Higher speed for wood

- Use lubrication when drilling into metal

- Always keep drill bits sharp

- Avoid loose hanging clothing or wearing jewellery

- Wear eye protection when operating a machine like this

If you have never used a drill machine before this article will help you with the basics. To gain more experience you have to use your machine often and experiment with the different abilities of the tool. Hope this article helped you today.

Happy drilling!